Table of contents

Key Takeaways

-

Email and phone calls top the list of supply chain collaboration methods, but they also impede efforts to reduce disruptions.

-

Collaborative, multienterprise applications help organizations rapidly digitalize supply chain issue management processes, improve visibility, and kick off Industry 4.0 transformation efforts.

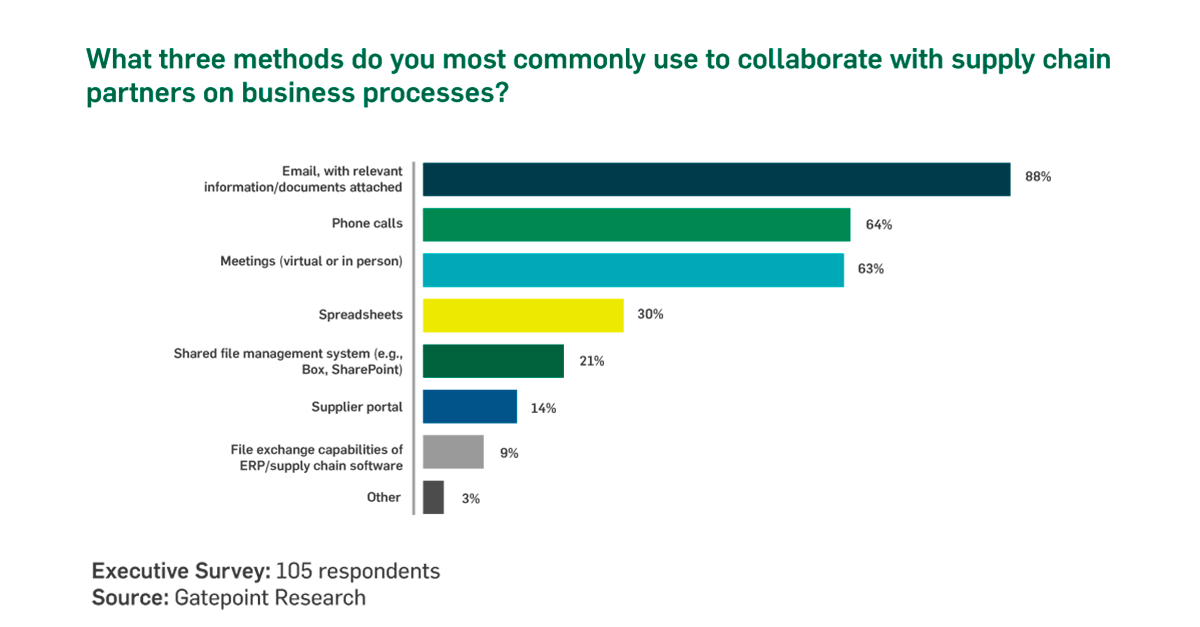

Email, phone calls, and a combination of in-person and virtual meetings are the top forms of supply chain collaboration, according to a recent survey of executives at manufacturing organizations.

The Gatepoint Research survey of 105 company leaders—including managers, directors, vice presidents, and C-level executives—also revealed that spreadsheets and file management systems round out the top five forms of supply chain collaboration.

Companies that have yet to adopt digital technology in their supply chain or are just beginning their supply chain transformation efforts must take action now.

But supply chain professionals and experts warn that these traditional communication tools may also impede efforts to improve on-time, in-full (OTIF) delivery performance and reduce supply chain disruptions. A new breed of collaborative, multienterprise applications offer significant benefits over traditional communication tools. These include:

- Complete visibility into issue management processes with real-time dashboards

- Faster supply chain issue resolution times

- A single, centralized source of data—and truth—for all supply chain partners

- Structured, workflow-driven, and configurable supply chain issue resolution processes

Collaborative, multienterprise work management solutions also offer improved root cause analysis capabilities and support for continuous business process improvement methodologies like Six Sigma.

A smarter form of supply chain collaboration

Unstructured and decentralized manual communication methods like phone calls, emails, and spreadsheets can prevent manufacturing organizations from achieving full visibility into supply chain issues that can lead to disruptions, according to supply chain professionals and industry analysts.

At the same time, collaborative multienterprise applications can help organizations rapidly digitalize supply chain issue management processes, improve visibility, and kick off Industry 4.0 transformation efforts.

“Adopting a multienterprise work management platform has dramatically improved the overall performance of our value chain," said Steve Hydzik, the retired Vice President and Global Head of Manufacturing and Supply Chain, EA, and New Technologies at The Merck Group KGaA. "Everyone is on the same page and working from the same digital source of truth to provide transparency. We don’t need to search through emails and spreadsheets to see what is going on, what needs to happen next, and why something happened. We’ve cut our incident resolution times by 5x, and the visibility has helped us prevent issues from recurring.”

Simon Ellis, an IDC Program Vice President and leader of the Supply Chain Strategies Practices at IDC Manufacturing Insights, warns that companies that haven't launched Industry 4.0 supply chain transformation efforts risk falling behind.

"Companies that have yet to adopt digital technology in their supply chain or are just beginning their supply chain transformation efforts must take action now. These companies can start by exploring ways to deploy enabling technology with agile processes,” Ellis wrote in an IDC report. “These processes should support end-to-end collaboration, provide actionable visibility, and enable data sharing between partners both inside and outside the organization and across all stakeholder functions.