Table of contents

Key Takeaways

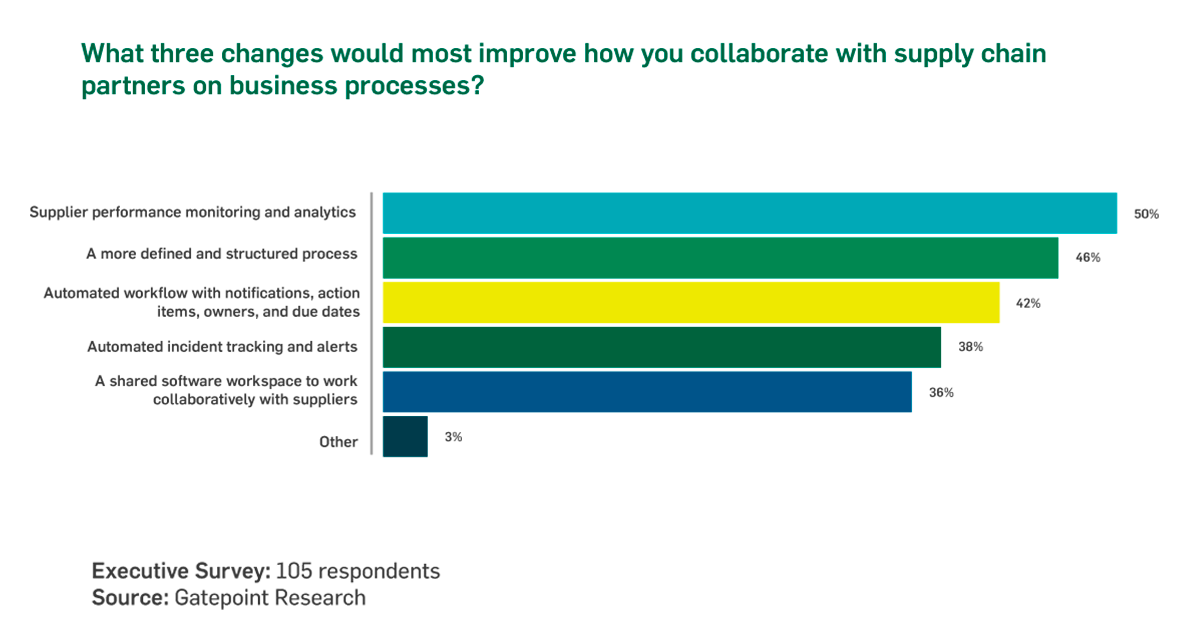

- Half of manufacturing executives wish they had a better way to monitor the performance of supply chain partners.

- A new multienterprise work management solution delivers workflow-driven and configurable issue resolution processes as well as the ability to closely monitor the performance of suppliers with real-time dashboards.

Half of the executives at manufacturing companies wish they had a better way to monitor and measure the performance of supply chain partners—and nearly half think a more structured process for managing supply chain issues would help them collaborate with greater effectiveness, according to the results of a new survey.

Gatepoint Research asked 105 executives at manufacturing companies——including managers, directors, vice presidents, and C-level executives—what would most improve how they collaborate with supply chain partners on business processes.

In addition to improved performance monitoring and structured issue resolution and supply chain collaboration processes, many executives indicated a desire for automated supply chain issue management workflows, greater visibility through automated incident tracking and alerts, and a shared workspace to work collaboratively with suppliers.

A smarter way to monitor the performance of supply chain partners

The good news for manufacturers is that a new collaborative, multienterprise work management solution delivers workflow-driven and configurable issue resolution processes as well as the ability to closely monitor the performance of suppliers with real-time dashboards. With Agile Process Teams for Supply Chain Issue Management (APT-SCIM), manufacturers and their supply chain partners can:

- Get full visibility into the status of ongoing, past due, and critical issue resolution processes.

- Easily identify problematic supply chain partners that need help.

- Analyze the historical data to help identify the root case and implement permanent solutions.

Top supply chain teams are also using APT-SCIM to support continuous business process improvement methodologies like Six Sigma and achieve operational excellence across their end-to-end supply chains. Watch this quick video with the former head of supply chain at a global manufacturer for more on how digitalization can fuel continuous improvement efforts: