Table of contents

Adding value to the role of packaging in the pharmaceutical supply chain is something West-European contract packager Tjoapack does best. For more than 25 years, the Etten-Leur, Netherlands-based independent contract packager has been introducing improvements in packaging products and techniques for pharmaceutical manufacturers and hospital pharmacies, with patient safety at the core of its mission. The first company in Europe to put barcodes on unit doses, Tjoapack continues to pave the way for supply chain efficiency and transparency, as the industry prepares to meet serialization requirements of the US Drug Supply Chain Security Act (DSCSA) and the EU Falsified Medicines Directive (FMD).

A worthy mission

In 1989, CEO Erik Tjoa launched Tjoapack. “His aim was to add value, not just put a tablet in a blister,” Tjoapack Business Development Director Bas de Gooijer says. In its first year of business, Tjoapack introduced the application of barcodes to unit dose blister packs. “Nobody in Europe was doing this,” de Gooijer says. As a result of this enhancement, medicines now can be identified right up until the moment they are consumed.

“We work hard to help our customers achieve their business objectives through a well-designed packaging process,” de Gooijer says, “never forgetting that at the end of the day, we are supplying drugs to people who are not well and need to get well.”

Today, 1.3 billion oral solid dosages packaged by Tjoapack find their way to patients across the globe.

“Centre of Excellence”

In 2006, with anti-counterfeiting legislation on the horizon, Tjoapack took action to respond to the regulation-related developments in the industry. “Very early on, we started talking to our customers and peers in the industry about how to implement serialization in our facilities,” Director of Corporate Strategy Dexter Tjoa says.

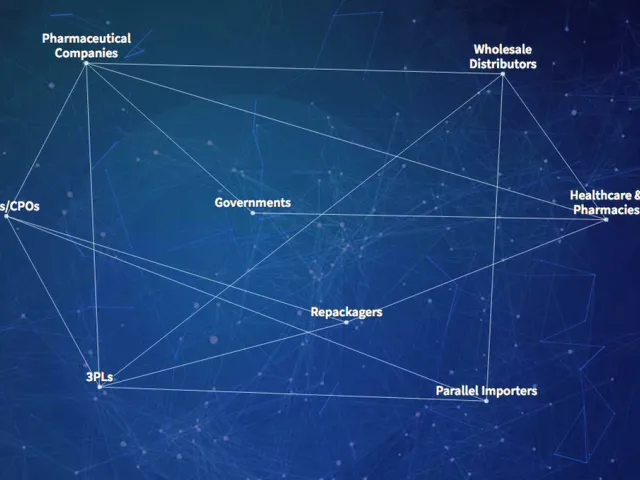

In 2008, Tjoa explains, Tjoapack set up a Track and Trace Centre of Excellence “to show that mass serialization and aggregation—building up the pedigree from a single tablet to the complete shipment—was technically possible.” The Centre provides a cooperative research and development platform for Tjoapack and its partners with the sole mission to improve patient safety and compliance through supply chain efficiency and transparency.

In Europe, Tjoapack was the forerunner in serializing for a complete packaging line, according to de Gooijer. “We gained our first serialization experience ten years

“Thanks to our efforts early on,” de Gooijer says, “we are now ready for the new EU directive that will make serialization a legal requirement for all our customers’ packaging.”

Regulatory readiness

A ten-year head

“Whenever there’s an update to legal requirements,

Still, de Gooijer points out, Tjoapack’s preparedness is just one hurdle overcome. “My biggest worry is that clients will not be ready to start implementing in time, leaving us with little time to serve all clients before February 9, 2019,” he says.

In order to help combat this concern, and enable customers to meet the varying global regulations on time, Tjoapack made the decision in December 2016 to partner with TraceLink, leveraging the TraceLink Life Sciences Cloud platform for an easy, fast, and secure path to compliance for its 50 plus customers.

“The value in the TraceLink

“In 18 months everything has to be validated,” de Gooijer notes, referring to the EU FMD serialization deadline of 2019. “I would strongly advise companies to start onboarding with CMOs as soon as

“With TraceLink, we can provide our customers an agile track and trace solution, well ahead of regulatory deadlines,” Tjoa says.

As the market leader in the Benelux for pharmaceutical packaging and serialization, “Tjoapack takes pride in strong partnerships that are in step with our Centre of Excellence and our mission,” Gooijer says. “We feel confident that in TraceLink we have a partner who ultimately shares our values in ensuring patient safety.”