Table of contents

Overview

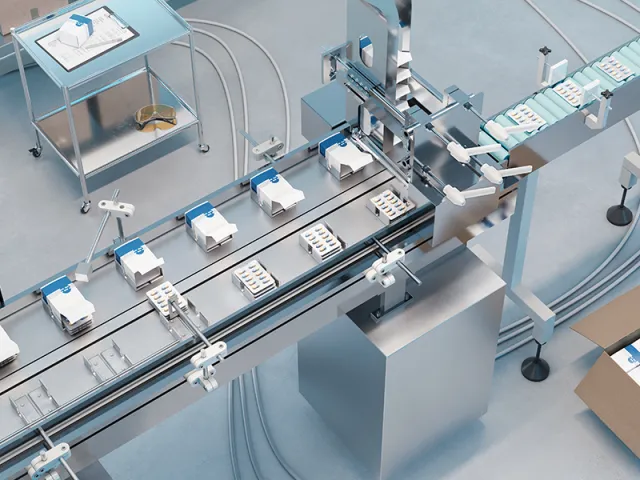

The SOM End of Batch transaction is an XML-based message used to record the completion of a serialized packaging or production batch. This transaction is critical for ensuring the secure and compliant transition from packaging operations to downstream distribution activities. It is typically triggered at the end of a packaging run, where all serialized units have been commissioned, inspected, and are ready for aggregation, shipment, or QA evaluation.

Initiated from within TraceLink’s Enterprise Serialization Management (ESM) platform, the transaction adheres to GS1 EPCIS 1.2 standards and provides a digital record of batch closure, enabling downstream systems to act on the completed batch accordingly.

Key Use Cases

- Mark the formal completion of a serialized packaging batch in ESM.

- Trigger downstream processes such as aggregation or QA review.

- Provide a digital checkpoint for serialized operations to ensure data integrity.

- Support compliance with DSCSA, EU FMD, and other global serialization mandates.

- Enable auditability and traceability of packaging operations.

- Serve as a control mechanism to prevent further changes to the batch after closure.

Data Elements Included

An EPCIS 1.2 – SOM End of Batch transaction includes:

- Event Type: ObjectEvent with business step "packing" or "commissioning" and action "observe" to denote the final state of serialized units in the batch.

- Serialized Product Identifiers (EPCs): SGTINs of all serialized units included in the batch.

- Event Time and Time Zone: The exact timestamp when the batch completion was recorded, including time zone offset.

- Read Point: The location (physical or logical) where the end-of-batch event was captured, such as the packaging line or serialization server.

- Business Location: The facility (GLN or internal identifier) where the batch was completed.

- Disposition: Typically set to "batch_completed", "ready_for_review", or "pending_QA" to indicate readiness for next steps.

- Batch ID: Unique identifier for the packaging or production batch being closed.

- Product GTIN(s): The Global Trade Item Numbers associated with the serialized units in the batch.

- Quantity (optional): Total count of serialized units in the batch.

- Aggregation Hierarchy (optional): Parent-child relationships if serialized units were aggregated into containers or cases.

- Digital Signature (optional): For data integrity and audit compliance.

- Comments or Notes (optional): Free-text field for additional context, such as packaging line notes or QA observations.

Benefits of EPCIS 1.2 – SOM End of Batch

- Ensures serialization completeness and data integrity at the end of packaging runs.

- Serves as a control point to trigger QA or aggregation workflows.

- Enables full traceability and audit readiness for serialized batches.

- Reduces manual errors by digitally recording batch closure events.

- Enhances compliance with global regulatory requirements.

Business Process: EPCIS 1.2 – SOM End of Batch

The SOM End of Batch transaction may fit into the serialized packaging and distribution workflow as follows:

- Serialized units are commissioned and optionally aggregated on the packaging line.

- QA checks are performed as required.

- Once all units are validated, the SOM End of Batch (EPCIS 1.2) transaction is triggered.

- Serialized data is locked for the batch, and downstream systems (e.g., QA, WMS, ERP) are notified.

- The batch is now eligible for aggregation, shipment, or further processing.

How TraceLink Supports EPCIS 1.2 – SOM End of Batch

TraceLink’s OPUS Platform, powered by B2N Integrate-Once™, enables end-of-batch serialization management by:

- Allowing automated or manual triggering of End of Batch events.

- Capturing EPCIS 1.2-compliant data with complete serialization context.

- Notifying downstream systems and partners of batch readiness.

- Supporting dashboards and audit logs for batch traceability and compliance.

- Ensuring secure communication with optional digital signatures and validation rules.

Explore More Serialization & Compliance Capabilities

- SOM ESM Aggregation – Record parent-child relationships for serialized packaging.

- SOM ESM Take Product Sample – Log the removal of units for inspection or testing.

- SOM ESM Sales Shipment – Record serialized shipments.

Need Help Implementing EPCIS 1.2?

Contact Us to learn how our OPUS Platform and B2N Integrate-Once™ model can help you improve production and packaging visibility, increase operational efficiency, and maintain traceability across your life sciences and healthcare supply chain.