Table of contents

Overview

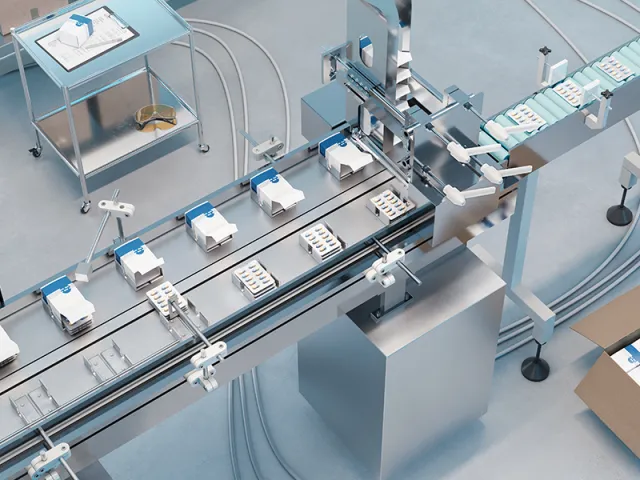

The SOM ESM Disaggregation transaction is an XML-based message used to document the disaggregation of serialized pharmaceutical products—removing child units from a parent container (e.g., pallet or case). This transaction complies with GS1 EPCIS 1.2 standards and works in conjunction with Enterprise Serialization Management (ESM) platforms.

Disaggregation is often required when a flagged order or container must be broken down for order fulfillment, inspection, sampling, or reallocation. With TraceLink’s OPUS Platform and B2N Integrate-Once™ architecture, the SOM ESM Disaggregation transaction ensures serialized traceability, regulatory compliance, and operational control.

Key Use Cases

- Document the removal of serialized child items from a parent container (e.g., pallet → cases or units).

- Support QA, track and trace, or logistical operations requiring unit-level tracking across multiple packaging configurations.

- Enable serialized traceability when aggregated containers are broken down.

- Maintain compliance with DSCSA, global track and trace, and internal SOPs for high-risk, high-volume product handling.

- Provide a secure, auditable record of disaggregation decisions and actions.

- Integrate disaggregation data with serialization repositories, ERP, and WMS systems.

Data Elements Included

An EPCIS 1.2 – SOM ESM Disaggregation transaction includes:

- Event Type: AggregationEvent with action = DELETE, indicating disaggregation.

- Parent EPC: Serialized identifier of the container being disaggregated (e.g., case or pallet).

- Child EPCs: Serialized identifiers (SGTINs) of the units being removed from the parent.

- Event Time and Time Zone: Timestamp when the disaggregation event occurred.

- Read Point: Physical location where the disaggregation took place (e.g., QA station, warehouse dock).

- Business Location: GLN or internal location code of the site performing the disaggregation.

- Business Step: Typically “disaggregation” or “rework” to reflect the intent of the action.

- Disposition: Indicates the status of the disaggregated items (e.g., “under_investigation”, “quarantined”, “available”).

- Reason Code (optional): Explains why the disaggregation occurred (e.g., “QA_REWORK”).

- Digital Signature (optional): For regulatory-grade data integrity and audit readiness.

- Comments or Notes (optional): Free-text field for investigator or compliance documentation.

Benefits of EPCIS 1.2 – SOM ESM Disaggregation

- Supports DSCSA/global track and trace compliance by maintaining serialized traceability post-disaggregation.

- Enables unit-level visibility for flagged or high-risk shipments.

- Provides secure, auditable records of disaggregation events for investigations or inspections.

- Integrates with ESM, ERP, and QA systems to automate downstream workflows.

- Improves operational control and decision-making during tracing and investigations.

Business Process: EPCIS 1.2 – SOM ESM Disaggregation

The SOM ESM Disaggregation transaction is typically used in the investigation or rework stage of a distribution or QA workflow:

- Aggregated units (e.g., pallet or case) must be broken down for inspection, sampling, or pack/pack/ship processes.

- SOM ESM Disaggregation (EPCIS 1.2) is triggered to formally record the disaggregation event.

- Serialized child units are tracked individually through sampling, quarantine, or reallocation.

- TraceLink logs the disaggregation event for full traceability and compliance reporting.

How TraceLink Supports EPCIS 1.2 – SOM ESM Disaggregation

TraceLink’s OPUS Platform, powered by B2N Integrate-Once™, enables secure and compliant disaggregation by:

- Triggering disaggregation events directly distribution, material handling, or QA investigations within TraceLink’s Enterprise Serialization Management (ESM) platform.

- Breaking parent-child relationships between serialized containers and their contents using EPCIS 1.2-compliant AggregationEvents with action DELETE.

- Capturing disaggregation event data in real time, including reason codes for full traceability.

- Distributing disaggregation records to serialization repositories, internal compliance systems, and downstream partners as needed.

- Providing dashboards and audit trails to track which products were disaggregated, by whom, and why—ensuring readiness for regulatory audits.

- Supporting secure, standards-based communication with optional digital signatures to maintain data integrity and non-repudiation.

Explore More Serialization & Compliance Capabilities

- SOM ESM Aggregation (EPCIS 1.2) – Record parent-child relationships for serialized packaging.

- SOM ESM Take Product Sample (EPCIS 1.2) – Log the removal of units for inspection or testing.

- SOM ESM Sales Shipment (EPCIS 1.2) – Record serialized shipments.

- SOM ESM Sales Shipment (TL XML) – Record serialized shipments.

Need Help Implementing EPCIS 1.2?

Contact Us to learn how our OPUS Platform and B2N Integrate-Once™ model can help you automate serialized disaggregation and maintain traceability across your life sciences and healthcare supply chain.